Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

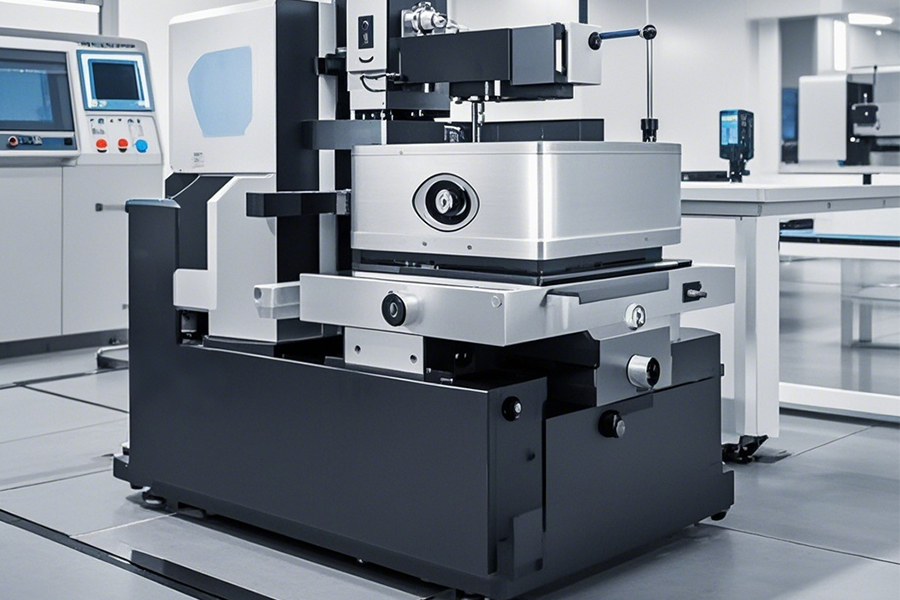

Application scope of precision CNC wire cutting

1. Mold parts processing

Mold manufacturing is one of the important application fields of precision CNC wire cutting. In mold manufacturing companies such as Airy Precision Machinery, CNC wire cutting technology is widely used to process various mold parts. For punching dies, whether it is a concave die or a convex die, the shape of the cutting edge is complex and the precision requirements are extremely high. Precision CNC wire cutting can accurately cut out cutting edges that meet dimensional accuracy and shape accuracy according to design requirements. Moreover, when processing injection molds and die-casting molds with complex cavities, wire cutting can easily cope with complex internal contours, providing guarantees for high-quality production of molds. This not only improves the processing accuracy of the mold, but also effectively shortens the mold manufacturing cycle and reduces production costs.

2. Processing of medical diagnostic equipment and accessories

Medical diagnostic equipment has almost stringent requirements on the accuracy and quality of accessories, and precision CNC wire cutting just meets this demand. For example, in the processing of some small medical sensor parts, these parts are often complex in shape and small in size, and traditional processing methods may not be able to achieve the required accuracy. CNC wire cutting can accurately cut out parts that meet the design through its high-precision electrode wire motion control. In addition, for some accessories such as high-precision frames used in medical imaging equipment, wire cutting can ensure their surface quality and shape accuracy, thereby ensuring the reliability and accuracy of medical diagnostic equipment and providing strong support for the medical industry.

3. Stage lighting parts processing

The realization of stage lighting effects is inseparable from various high-precision lighting parts. In the manufacturing of stage lighting parts, precision CNC wire cutting has a unique place. For example, some special shapes of sunshades, reflectors, etc. require precise contours and good surface quality to achieve ideal light control effects. CNC wire cutting can cut complex patterns and curves on metal materials according to design requirements, meet the special needs of stage lighting for light reflection, refraction and shielding, and enable stage lighting to create a variety of colorful effects.

Technical points of precision CNC wire cutting

1. Programming technology

Programming is the core link of precision CNC wire cutting processing. Operators need to use professional programming software to generate CNC instructions based on the two-dimensional or three-dimensional drawings of the parts. During the programming process, the radius compensation of the electrode wire must be accurately considered. Since the electrode wire has a certain diameter, it will be offset during the cutting process. If it is not accurately compensated, it will lead to part size deviation. In addition, the planning of the cutting path is also crucial, including determining reasonable starting and ending points to avoid traces or precision problems at the starting and ending positions of the cutting, and ensure the overall accuracy of the parts.

2. Selection and tension control of electrode wire

The selection of electrode wire directly affects the processing effect. Common electrode wire materials include molybdenum wire, tungsten wire, etc. Molybdenum wire has good toughness and conductivity and is suitable for general processing occasions; tungsten wire is more suitable for processing materials with higher hardness. At the same time, the tension control of the electrode wire is very critical. Appropriate tension can ensure the stability of the electrode wire during the cutting process and prevent it from shaking. If the tension is too large, the electrode wire is easy to break; if the tension is too small, it will affect the cutting accuracy and cause problems such as cutting trajectory deviation.

3. Reasonable setting of processing parameters

The setting of processing parameters determines the quality and efficiency of precision CNC wire cutting. The main parameters include pulse width, pulse interval, discharge current and cutting speed. Pulse width and pulse interval affect the discharge energy, and they need to be adjusted reasonably for workpieces of different materials and thicknesses. Excessive discharge current may cause burns on the workpiece surface and excessive electrode wire loss; too small a discharge current will result in slow cutting speed and low efficiency. The cutting speed should be determined according to the material and complexity of the workpiece. Too fast will cause the electrode wire to vibrate and affect the accuracy, while too slow will increase the processing time.

In short, precision CNC wire cutting has shown a wide range of application prospects in the fields of mold parts, medical diagnostic equipment and accessories, stage lighting parts, etc. Mastering its technical points is of great significance to improving processing quality and efficiency and expanding its application scope, and it is driving these industries towards a more precise and efficient direction.

Author:

Mr. Ares team

E-mail:

November 08, 2024

November 07, 2024

Mail a questo fornitore

Author:

Mr. Ares team

E-mail:

November 08, 2024

November 07, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.