Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Precision CNC broaching has a wide range of application scenarios. In the automotive manufacturing industry, there are many hole systems and groove structures with extremely high precision requirements on engine cylinder blocks, cylinder heads and other parts. Precision CNC broaching can quickly and stably process standard inner hole keyways, splines, etc. to ensure the performance and reliability of the engine. This technology is also widely used in the aerospace field.

For example, in the special shape processing of aircraft landing gear and turbine engine blade roots, precision CNC broaching can achieve one-time molding of complex contours to meet the stringent requirements of high strength and high precision of aviation parts. In addition, in precision mold manufacturing, precision CNC broaching can also be used to process some mold cavities and cores with specific shapes and high-precision dimensional requirements, effectively improving the quality and service life of the mold.

Its technical points are first reflected in the tool. The broach is a key tool for precision CNC broaching. It has multiple cutting teeth, and the size and shape of each cutting tooth are carefully designed. The material of the broach is usually high-performance high-speed steel or cemented carbide to ensure sufficient hardness, wear resistance and heat resistance. During the manufacturing process, the parameters such as the rake angle, back angle, and edge width of the broach cutting teeth must be strictly controlled. These parameters directly affect the cutting force, chip shape and machining surface quality. For example, a reasonable rake angle can reduce the cutting force, while the back angle can avoid the friction between the back face of the broach and the workpiece.

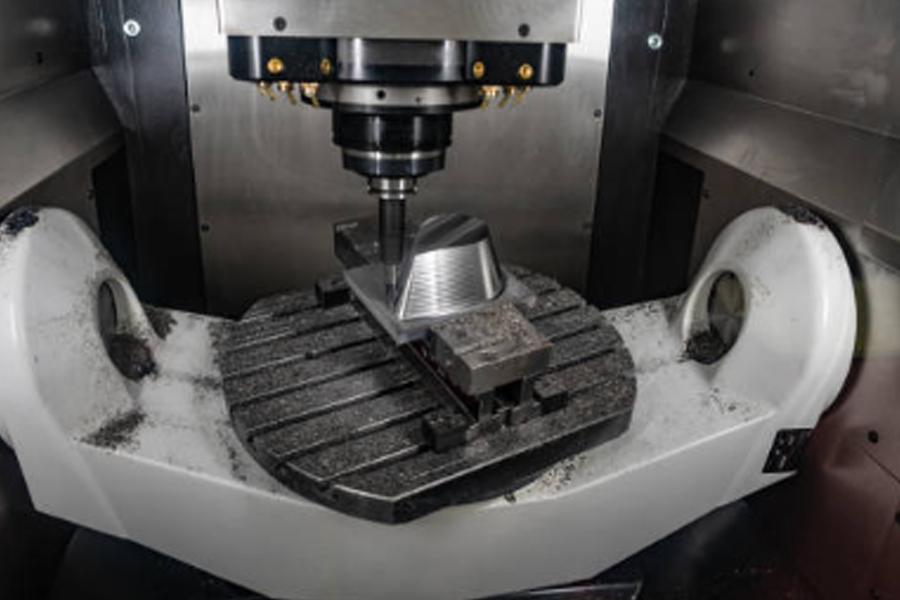

The accuracy and stability of machine tools are crucial to precision CNC broaching. High-precision CNC broaching machines have precise motion control systems that can accurately control the linear motion speed, stroke and positioning accuracy of the broach. The rigidity of the broaching machine should be good to withstand the large cutting force during broaching and avoid the reduction of machining accuracy due to deformation of the machine tool. At the same time, the CNC system should be able to realize multi-axis linkage control to meet the processing requirements of complex-shaped workpieces, and have real-time monitoring and feedback functions to monitor parameters such as force, temperature, vibration, etc. during the broaching process, and make timely adjustments if abnormalities occur.

The reasonable setting of processing parameters is also a key link. The selection of cutting speed should comprehensively consider factors such as broach material, workpiece material and processing requirements. Too high cutting speed may lead to increased broach wear and poor surface quality; while too low cutting speed will reduce production efficiency. The feed rate should be determined based on the broach pitch and the machining allowance of the workpiece. The appropriate feed rate can ensure the smoothness and machining accuracy of the cutting process. The cutting depth needs to be accurately set according to the shape, size and precision requirements of the workpiece to ensure that the machined surface of the workpiece is not damaged while removing the allowance.

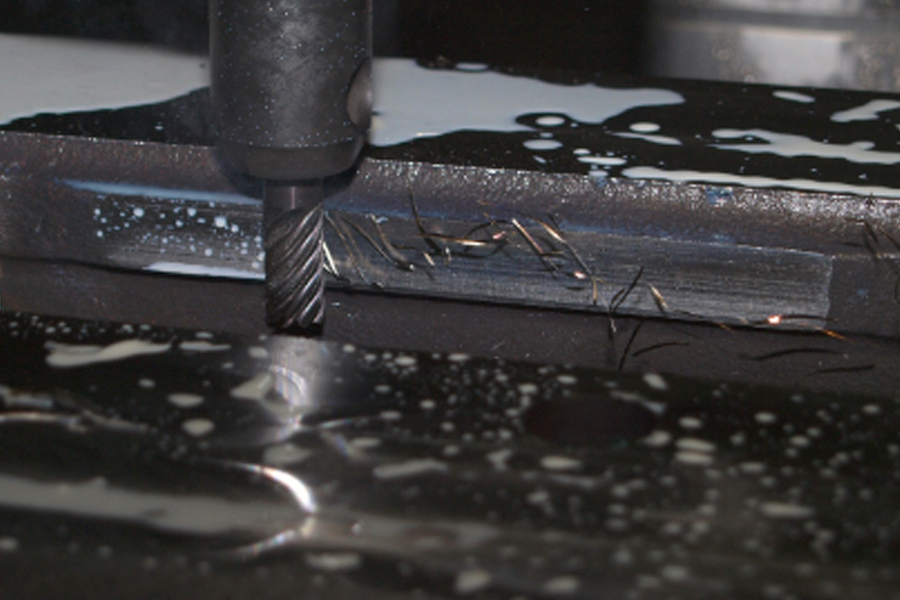

The cooling and lubrication system is also indispensable in precision CNC broaching. Since a large amount of heat and chips will be generated during the broaching process, good cooling and lubrication can reduce the cutting temperature, reduce broach wear, improve the machining surface quality and extend the service life of the broach. The cooling and lubricating fluid should be selected according to the workpiece material and the broach material. At the same time, the flow, pressure and injection position of the cooling and lubricating system should be reasonably controlled to ensure that the coolant can fully reach the cutting area.

Precision CNC broaching has been widely used in many important industries due to its unique advantages. Mastering the key technical points such as tool design and manufacturing, machine tool equipment requirements, process parameter setting, cooling and lubrication can fully exert the effectiveness of precision CNC turning, provide strong guarantees for the production of high-precision and high-quality parts in high-end manufacturing, and promote the continuous development of mechanical processing technology towards a more precise and intelligent direction.

Autore:

Mr. Ares team

E-mail:

November 20, 2024

November 12, 2024

Mail a questo fornitore

Autore:

Mr. Ares team

E-mail:

November 20, 2024

November 12, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.